Foreword

Alot of things have changed in the earthbag building movement since Kelly Hart and I started to disseminate free earth- bag information on the Internet at Earthbag Building.com in 2007 and a few years later at NaturalBuildingBlog.com (formerly Earthbag ). Back then, there were not very many earthbag buildings or resources available. Today, there are thousands of earth- bag buildings, countless online videos, as well as many websites and blogs, and numerous books.

The most prolific changes in this movement have come from abroad, in poor countries, where the need for safe, affordable housing, schools, clinics, eco toilets, and water tanks is staggeringly high. Developing countries urgently need these things. Other building materials and methods are often not affordable or practical.

Earthbag building is now very popular in Mexico, South America, Africa, Asia, and other places. Some of the most exciting development work is being done in Nepal since the 2015 earthquakes rocked that country. What caught the world’s attention was the vast number (hundreds of thousands) of concrete and brick buildings that were destroyed, while all 55 earthbag buildings in Nepal that had been built before the quakes survived without major

structural damage.

Earthbag building is quickly catching on in Nepal as the safest, strongest, lowest cost, most effective way of building. For instance, a 6-classroom school can be built in about two months by local villagers for the cost of a car. These buildings are so strong that you could drive a speeding vehicle into the walls, detonate grenades, or shoot them with a machine gun with only minor damage.

In my article Low Cost Village Housing for Nepal on our blog, I explain how the greatest need for housing in Nepal is in poor rural villages. Most of these places are in remote mountainous areas far from roads. Not only can these villagers not afford cement and steel for conventional building, it’s not practical to carry these heavy materials 1–2 days over steep mountain passes. Earthbag building is an excellent choice in this situation.

The following projects illustrate the wide range of uses for earthbags, and some of the many benefits.

Since 2015 Good Earth Global (goodearth ) has built four schools, one learning center, over 20 houses, one meeting center, and four model eco toilets in Nepal and India.

They have taught earthbag building techniques to almost 1,000 rural village builders, students, engineers, architects, and community leaders in Nepal and India. They won the “Best Rural Design” award at a competition organized by the

Nepal Engineering Association.

This NGO, partnered with Anna University, a leading Indian technical university, co-organized an international earthbag conference in India, and supervised the construction of a model Earthbag Meeting Center on the university’s

Madurai campus.

Good Earth Global has designed prototype earthbag toilets that are inexpensive, ecologi- cally sustainable, and easily built using local labor and materials. Toilets can be built by four workers in two days at $282 each for materials and labor. With sufficient support, Good Earth Global hopes to build thousands of earthbag toilets throughout India, potentially saving hundreds of lives daily.

In April 2017, Nepal’s Ministry of Urban Development approved and published Good Earth Global’s earthbag designs in the “Design Catalogue for Reconstruction of Earthquake Resistant Houses,” giving millions of earthquake victims the opportunity to use government aid money to build safe and affordable earthbag homes. With this pioneering decision, Nepal became the first country in the world to officially endorse earthbag technology, and now emerging

as a worldwide leader in sustainable building and development.

First Steps Himalaya had just completed its first earthbag building days before the magnitude 7.9 earthquake struck Nepal in 2015. Despite being in one of the worst-affected areas where almost all buildings were flattened, the earthbag teacher training center survived with just a few cracks. First Steps Himalaya then organized an Earthbag Building Summit in Kathmandu in September 2015.

Since then, they have provided hands-on training on earthbag building to numerous Nepali and international organizations and individuals. The charity has completed nine earthbag classrooms and an eight-bedroom accommodation building for trainees, with many more projects planned.

Over the last nine years, Edge of Seven (edgeofseven.org) has completed four earthbag dormitory buildings for girls, and six classrooms using the method. Community leaders reported: “These were the only buildings where we truly

felt safe after the earthquake.”

Woven Earth assisted non-profit Carisimo with several dozen earthbag houses in Nepal. Acting as technical advisors, in collaboration with Loving Arms Mission, Woven Earth assisted rural farmers in building 16 farm houses, some of these as training for the locals. And in collaboration with Common Action for Sustainable Development, they organized training for local workers to build one large Savings and Credit Cooperative Building

for a local women’s cooperative.

Woven Earth and Loving Arms Mission, with support from Kathryn Kaspar, have successful- ly carried out projects in which one member of each family worked on the construction of multiple houses in exchange for receiving one of the houses upon completion. Teaching the locals not only provides them with useful skills but also greatly reduces the cost of labor for the project. The local acceptance and understanding of a new building technique is also more likely

because the recipients are involved in every step of the construction process.

Sacred Earth Trust (SET, sacredearth trust.org) is an NGO based in India working on sustainable development in sacred sites. SET has been building an eco training and plastic upcycling center to demonstrate low-cost effective technologies which are also earthquake resilient.

To address issues regarding availability of space a “thin-wall” technique was adopted for local use to construct the office and machine rooms on site. Instead of using common 18-inch (46 cm)

wide earthbags, the thin-wall method was adapted and resulted in 12-inch (30 cm) wide walls.

The project demonstrated thin-wall earthbag building is practical for two-story structures on small lots in urban areas where code approval is required.

Dada Krpasundarananda (news.dadaksa.

com) is a monk who has gained extensive experience with building and teaching others to build Super Adobe domes. In Nicaragua, Mongolia, New Zealand, Ireland, Ghana, Canada, and other countries, Dada has been building/leading about one project a year on average. All the projects were domes, and generally they were for training purposes. He is seeing more interest now in alternative methods of building and more houses built, some of those as a direct

result of his previous workshops.

Earthbag building is also growing in the Philippines, primarily for building hurricane resistant housing. One coastal village near Coron was devastated by Super Typhoon Yolanda in 2013, with about 90% of the houses in the village being completely destroyed. The Tamayo Foundation, a construction company in Manila, is funding 100% of a project to build a target goal of 100 earthbag houses.

Cyclone Pam hit Vanuatu as a category 5 cyclone in March 2015 and destroyed many houses and water tanks. For the first two weeks, the only clean water available in one village

came from the earthbag water tanks at the earthbag Women’s Center. The Tamayo Foundation has built 40 earthbag tanks since Cyclone Pam and they have started other women’s groups on seven islands. These affordable (half the price of plastic water tanks) and easy-to-build water tanks could help solve the water shortage problem all across the Pacific islands and other drought-stricken parts of the world.

Project Somos Children’s Village (project somos.org) created a Children’s Village for Guatemalan children and mothers, with homes, staff housing, a culture dome, a preschool, and a community hall using earthbags. The Village

is built to be eco-sustainable, with solar energy, rainwater capture, greywater recycling, and an

organic farm.

Those at the Mlambe Project (themlambe project.org ) in Malawi have been able to help hundreds of people by building schools with earthbags. This building technique addresses the “triple bottom line,” because it is environmental- ly, economically, and socially sustainable. Malawi

has a major deforestation problem that is causing serious flooding; earthbag building helps protect local forests by reducing the use of wood.

Phangan Earthworks (phanganearthworks.com) has built five earthbag structures on the tropical island of Koh Phangan, southern Thailand. The structures include two darkroom meditation domes, a large two-room toolshed,

and a spacious “cave” house that artfully combines granite, wood, and earth. The earthbag walls elegantly fill gaps between large boulders that were on the property.

Chiang Dao B&B in Thailand (chiangdao-roundhouses.com) was built with bags filled

with rice hulls — an abundant, low cost, local material. There are ten round buildings, mostly 5 meters across. Rice hulls are not load bearing, so the buildings are post and beam, with bamboo trellises on which the bags of rice hulls are attached. The cost to build one of these roundhouses is about $1,500, not including cost of local labor.

Japanese professor Akio Inoue has been a prolific earthbag builder and promoter, with about 30 projects, mostly earthbag domes on the campus of Tenri University in Japan; other projects are in India, Uganda, and elsewhere.

Japanese architect Kikuma Watanabe has also created many earthbag projects around the world. Chinese professor Sunny Tsai and Colombian architect Jose Andres Vallejo have designed and overseen numerous other earthbag projects.

Precision Structural Engineering (structure1.com) has provided structural engineering for over 20 earthbag homes and the Seeds of Learning School in Nicaragua.

This brief list of projects shows the impact that sustained effort can have. Almost all of the projects described here were completed on small budgets, relying on the help and generosity of volunteers and donors. These projects are way more than just a tally of buildings. They address very important issues: how earthbags help reduce deforestation and flooding, provide earthquake and hurricane resistance, reduce housing costs, provide clean toilets and water tanks, and make it possible to build in remote places where it’s impossible to transport other building materials.

I believe we are nearing a tipping point of significant change since the proof of concept and list of achievements is so overwhelmingly convincing that major acceptance will likely soon happen. After all, how many thousands of projects have to be built to demonstrate to the world, the media, and major NGOs that earthbag building is safe, affordable, and practical?

Let’s all work together to raise awareness of natural building methods such as earthbag to make a bigger impact in the world.

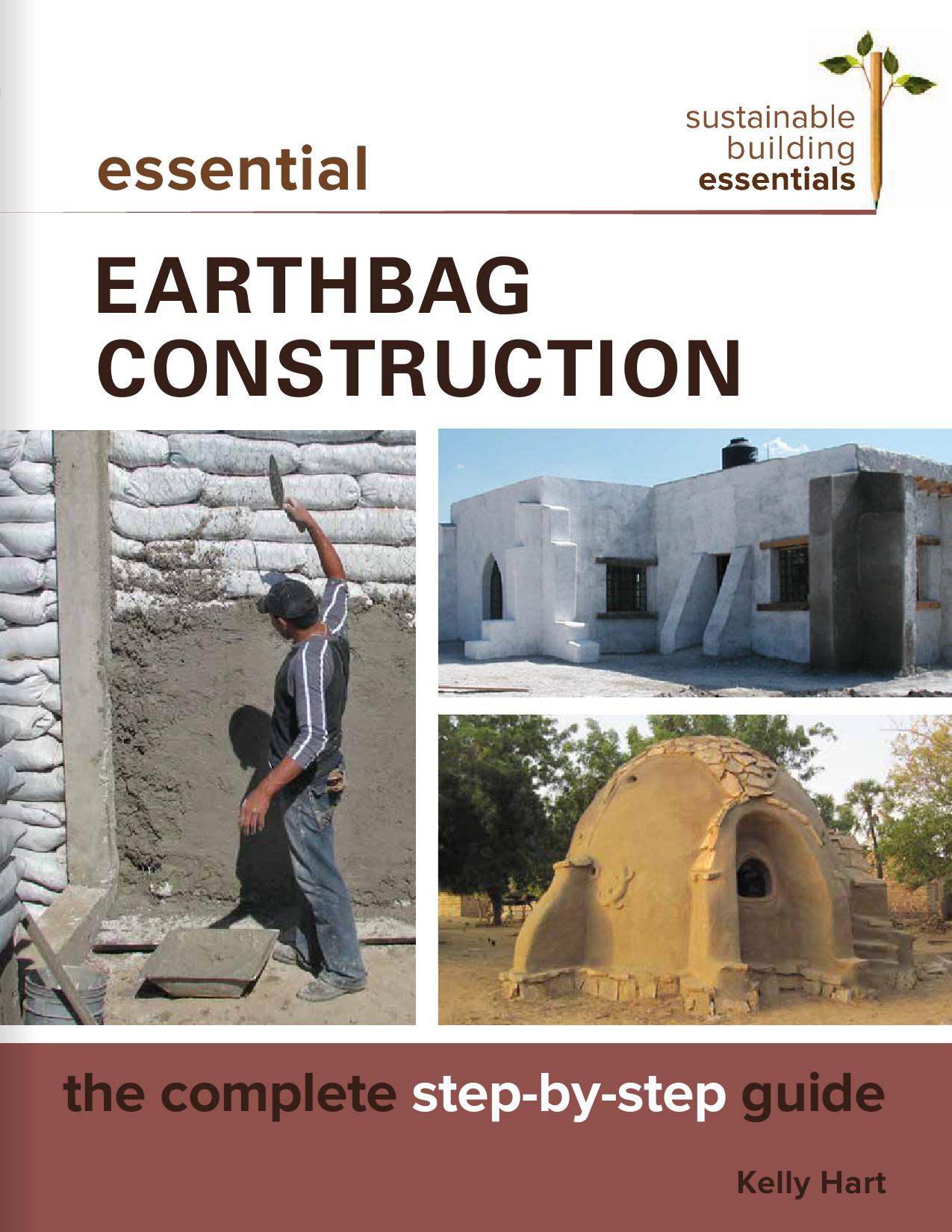

A Brief History of Earthbag Building

Bags of sand or dirt have been used to build military bunkers or divert flood waters since at least the end of the 18th century.

They are a good choice for this because they are easy to carry to where they are needed, can be quickly filled with local material, are inexpensive, and are quite effective at protecting people and property. Of course, these uses are generally only temporary. The use of sandbags (or, earthbags, as we refer to them here) for more permanent structures has only occurred in the last few decades.

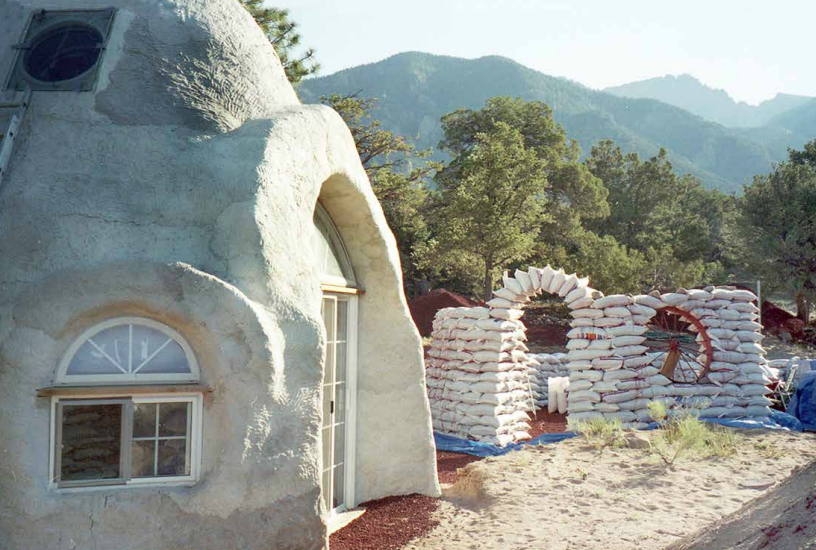

In 1976, at the Research Laboratory for Experimental Building at Kassel Polytechnic College in Germany, Gernot Minke started experimenting with ways to make housing by stacking fabric tubes filled with loose natural materials. Pumice showed particular promise because it is both lightweight and insulating.

At first, he built simple corbelled domes in an inverted catenary arch shape, using a rotating template to help place the tubes.

In 1978, Minke’s team built a vertical-walled house in Guatemala using pumice-filled cotton tubes that were soaked in lime-wash as a preservative. Vertical bamboo poles were placed at intervals on both sides of the filled tubes and tied with wire between them to provide stability to the wall. The bamboo was also tied into the foundation and the top beam to create an earthquake-resistant structure.

In 1984, Iranian-born architect Nader Khalili proposed filling bags with moon dust as a way to build shelters on the moon. He refined this idea for building on Earth by placing strands of barbed wire between the courses of bags, thus unifying the shell into a more monolithic and shock-resistant structure. Khalili evolved the sandbag idea into what he called Superadobe by filling polypropylene bags or long tubes with moistened adobe soil that would solidify as it

dried.

Khalili publicized his Superadobe concept widely and began conducting workshops and seminars on the techniques that he had developed, mainly at his California Institute of

Earth Architecture. Based on exposure to these ideas, many other people started experimenting with their own building projects. Joe Kennedy, Paulina Wojciechowska, Kaki Hunter, and Doni Kiffmeyer all initially studied with Khalili, and the more general term earthbag building became popular.

Paulina Wojciechowska wrote the first book on the topic of earthbag building: Building with Earth: A Guide to Flexible-Form Earthbag Construction, published in 2001. This was followed by the publication of Earthbag Building:

The Tools, Tricks and Techniques by Kaki Hunter and Doni Kiffmeyer in 2004. Several other excellent books have been published since then.

Akio Inoue has done extensive experimentation with earthbag dome construction, both on the campus of Tenri University where he taught in Japan and in India and Africa, where many other domes were built for assistance programs.

I first began experimenting with earthbag building in 1997, after producing a video program: A Sampler of Alternative Homes: Approaching Sustainable Architecture. I later documented my experience in building my own home in another program titled Building with Bags: How We Made Our Experimental Earthbag/Papercrete Home.

In 1999, Nader Khalili patented his Superadobe technique in the U.S. (despite the fact that patent law clearly states that such a patent cannot be obtained if the concept was publicized for over a year prior to the patent application). Khalili and his estate have rarely attempted to enforce the patent and say on their website, “Superadobe is a patented system (U.S.

patent #5,934,027) freely put at the service of humanity and the environment. Licensing is required for commercial use.”

Besides filling bags with adobe soil, many people have successfully filled bags with other materials, including crushed volcanic rock, crushed coral, non-adobe soils, gravel, and rice hulls.

Around 2009, Fernando Pacheco, a Brazilian engineer, experimented with using open mesh bags or tubing, similar to the sort of material commonly used to package bulky produce. He called his technique Hyperadobe and suggested that it has many advantages, such as creating a more monolithic structure and eliminating the need for barbed wire and mesh for stabilizing plaster.

Testing

In the mid-1990s, various engineering tests were performed on earthbag structures at Khalili’s Institute, proving the efficacy of his techniques and enabling building department approval for some specific designs.

In 2006, at the request of Dr. Owen Geiger of the Geiger Research Institute of Sustainable Building, the Department of Civil and Mechanical Engineering of the U.S. Military Academy at West Point conducted several controlled and computer-monitored tests to

determine the ability of polypropylene earth- bags filled with sand, local soil, and rubble to withstand vertical loads. Their written report concluded that “overall, the earthbags show promise as a low cost building alternative. Very

cheap, and easy to construct, they have proven durable under loads that will be seen in a single-story residential home. More testing should prove the reliability and usefulness of earthbags.”

Even with these tests (and many others), earthbag building has yet to be incorporated into the International Residential Code (IRC).

Nevertheless, hundreds of permanent and emergency earthbag dwellings have been built all around the world (and some of them are quite elegant). I wouldn’t be surprised if many of these earthbag homes are still standing long after their conventional counterparts have disintegrated.

As an example of the robust permanence of earthbag building, all of the more than 55 earthbag structures that existed in Nepal prior to the devastating 2015 earthquake survived with only cosmetic damage. In some instances, whole villages were flattened with the exception of a few earthbag buildings. This has not escaped the attention of the international aid community and the Nepalese authorities; they are now recommending that communities rebuild with earthbags.

Appropriate Uses for Earthbags

Earthbag construction is remarkably versatile, perhaps more than any other building technique. It can be employed both above and below ground without concern for rot or degradation. It can create thermal mass or an insulating barrier, depending on what the bags are filled with. It can be fashioned into a wide range of building shapes, from organically curvy to completely rectilinear, from domes to boxes — or combinations of any of these. It can be extremely durable, resisting fire, flood, earthquake, tornado, bullets, and time. It can also be quite economical — literally, dirt cheap.

The techniques are simple to learn; for the most part, the work can be done by unskilled labor.

The building shells are generally nontoxic, made of natural materials that can be returned to the earth or recycled at the end of their useful life.

Often, very little wood or industrial materials

are needed, so the buildings are environmentally benign. A simple rubble trench foundation may be all that is required, eliminating the need for massive concrete foundations. Besides buildings, earthbags can be used to build dams, cisterns, retaining walls, and other landscaping features.

What more could you want?

Of course, all of the above considerations depend on good design and proper execution for good results. As with any building method, it is essential to be educated about proper design principles and procedures before embarking on any project. This book will give you not only a better understanding of the technique of building with earthbags, it will give you all the information you need to actually do it.

Earthbag walls are usually rather thick and heavy, which does limit some of their possible uses. For instance, they may not be the best choice for interior walls, where space may be limited; they are not a good choice where plumbing or electrical needs to be run, or where there isn’t an adequate foundation to support the weight.

In most climates around the world, it is best for the shell of a habitable building to be insulated from the extremes of ambient temperatures in order to have a comfortable and energy-efficient dwelling. Unfortunately, most soils are

poor insulators, so filling earthbags with soil has limited utility. To remedy this, it is possible to either fill the bags with a more insulating material or to add a secondary insulating layer on the outside of the shell. Lightweight volcanic stone (such as scoria or pumice), perlite, vermiculite, and rice hulls are all insulating materials that can be used for fill. These materials are not available in all localities, or they might be too expensive for a given project. When investigating the possibility of building with earthbags, the availability of the most appropriate fill material needs to be a primary consideration.

While a wide range of building shapes are possible with earthbags, there are some design limitations. In general, vertical walls are quite stable when curved, but they usually require additional buttressing support when they are straight. Earthbags make great domes, but structures should be no larger than about 20 feet (6 meters) in diameter, and they cannot be hemi-spherical; catenary arches are the best dome shape to build. Domes need to be circular at the

base so that all of the forces around them are equally balanced; otherwise, there is the risk of deformation and failure. Furthermore, earthbag domes are best limited to fairly arid climates, as it is difficult to assure that the final plaster will always be watertight in wetter climates. Vaults should be avoided (except for very narrow ones that are well buttressed); they are simply too unstable. Walls that have many openings for doors and windows are probably best framed with wood because there are limits to how many such openings can be placed in an earthbag wall.

Most earthbag buildings are one story high, or just tall enough to accommodate a small loft area. While it is possible to build multi-story earthbag buildings, they would need to be carefully engineered to assure safety. I think that a basement with two additional stories above it would be the limit for any earthbag building.

Remodeling an earthbag building can present some challenges, especially in terms of cutting through existing earthbag walls for new doors or windows. If one anticipates the need to remodel or add more space to an earthbag building, it’s best to create the opening at the time of original construction and simply fill it in with temporary earthbags; when the time comes to make the changes, it is easy to just knock out the dummy bags.

Hanging heavy things on earthbag walls can present problems. It is best to anticipate the need for hanging things (like cabinets, mantels, and heavy artwork) during the construction phase — and incorporating structures that will allow attachments as the building goes up. It is possible to retrofit for hanging, but it can be awkward or inconvenient to do so.

A general problem with earthbag building is that you may have to jump through some extra hoops to obtain a building permit — if one is required. Earthbag technology is simply too new and too alternative to have generated the necessary impetus for uniform codes to have been adopted. This means that in order to be acceptable to the authorities, any given plan may need to be signed by a licensed engineer or architect who will vouch for its safety, and this can add to the time and expense of a project.

Contents

Acknowledgments

Foreword

Chapter 1: A Brief History of Earthbag Building

Chapter 2: Appropriate Uses for Earthbags

Chapter 3: Building Science Notes

Chapter 4: Material Specifications

Bags

Fill material

Barbed wire and other types of reinforcement

Plaster

Chapter 5: Tools

Chapter 6: Foundations

Chapter 7: Building Walls

Locate source of fill material

Filling bags

Placing barbed wire and twine

Laying bags in a pattern

Closing the top of the bag

Using a metal slider

Tamping the bags

Placing vertical reinforcement rods

Building domes

Chapter 8: Design Considerations and Constraints

Vertical walls9

Domes

Vaults

Buttresses

Bond beams

Door and window openings

Door and window bucks

Arches and other shapes

Spacing openings

Vertical reinforcement for openings

Lintels

Wall thickness

More than one story

Below-grade construction

Chapter 9: Plastering the Walls

Chapter 10: Floor and Roof Options

Slab on grade

Masonry floors

Adobe floors

Suspended floors

Roofs

Chapter 11: How to Include Utilities

Plumbing

Electrical

Heating

Ventilation

Cabinetry

Chapter 12: Strategies for Seismic Reinforcement

Chapter 13: General Budgeting Information

Chapter 14: Maintenance and Renovation

Chapter 15: Building Codes

Chapter 16: Other Uses for Earthbags

Retaining walls

Cisterns

Dams.

Root cellars and pantries

Sculpture and art Resources

Author’s websites

Other websites

Books

DVDs

Workshops

Bag supplies online

Index

About the Author

A Note About the Publisher