Preface

The learning of ‘Masonry and Concrete’ is imparted in Civil Engineering Degree, diploma and to trade apprentice courses, in various Colleges and Institutes. However, it has been my observation while working in Railways in various capacities, that large no. of Engineers, supervisors and artisans have to learn methods of proper working from their seniors, peers and few skilled artisans in the field. Several Hand books, and literature available in the market on the subject, generally have information but it is cloaked behind high level theory, tables, formulas and codal provisions and it is a difficult task for any person of average intelligence and patience, especially for field Engineer/Supervisor, to sift through the required information from these normally thick volumes. The B.S./I.S. Codes and so also the Specifications framed by several Government departments like CPWD and Railways demand the quality of a finished work but not guide about the method to achieve it, besides being worded in techno-legal language for reasons of having an upper hand while dealing with contractor. I understand that, in some organisations and in advanced countries a ‘Method Statement’ is prepared by a Technical Consultant for all works. even of basic nature, which is approved by the Technical Department owning the work and is followed at the field by all the Engineers, Supervisors and the Artisans. In Government departments in India, like Railways and CPWD, this is mainly left to the decision and the method adopted by the artisans and field supervisors.

The work is then as good as the artisans and Supervisors employed on the work. The B.S./I.S. codes give detailed specifications of the materials and the tender specifications make a mention of the same, but one finds that there are different set of specifications being followed in the field, mainly due to ignorance about the B.S./I.S. specifications, so much so that field supervisors have also become used to the “Chalta Hai” attitude, which gets strengthened, day by day, with their experience. An attempt has been made to provide the controlling specifications and field tests of the materials used in works and it has been deliberately avoided to reproduce the codes. While working as Principal Chief Engineer on Western Railway, I started work of preparing “Method statements for commonly used items of work in the Railways, with the assistance of Shri G.C.Jain, DyCE/Planning, W.Rly. and several SE(Work) of W.Rly., with the idea to make it a part of all contracts, in Western Railway. Shri Jain, retired from service and the process got delayed. The work has been now completed by Shri A.V.Dasare Sec. Engineer/ IRICEN and Shri N.R.Kale, Assistant Executive Engineer/IRICEN but the

format has been changed from that of a statement that of a guidebook. This Practical Guide book is expected to serve the field Supervisors as a substitute for ‘Method Statement’ and guide the artisans about the steps for the proper execution of work. I do not claim it to be a comprehensive treatise on the Science and art of ‘Masonry and Concrete’, as it has been the intention to make a very short and crisp presentation on the few factors that any field Engineer/ Supervisor would like to know for achieving proper quality of work. This is a collection of procedures and good practices and I am sure that the readers can enrich it further by their contribution and suggestions, which are welcome.

CHAPTER 1 MASON’S TOOLS

1.0 The various tools used by mason for his work can be grouped as follows.

a) Common tools: In this category all types of tools commonly used for setting the masonry work such as

Trowlels: Brick trowel, Nyla, Margin trowel, Gauging trowel, Angle trowel.

Floats: Wooden floats, Metal floats, Plumb bob

Mason’s square Line dori

Screed board/ Aluminium Box section.

Measuring Tape

b) Mortar Making tools: Generally these tools are used in making mortars for masonry.

Pharma Mixing tray Sand screen

Pan (Ghamela) Spade(Phawra) Bucket

Drum Punja

c) Levelling tools: These tools are used for setting the levels at the time of work.

Spirit level Level tube

d) Finishing tools: These tools are used for finishing work such as Sponge

M .S. Corners Cove corner Jointer/slicker

Convex or concave jointer

Vee Jointer Grapevine Jointer Brushes

d) Cutting tools: These are tools used for minor cutting or chpping work

Chisels Hammers Taccha Tile cutter

Portable Circular Saw

2.0 Common Tools

2.1 Trowels:

Trowels are the basic and traditional tools which have developed into many various shapes and sizes as per their functions. Some common types of trowels are as follows:

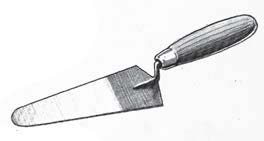

a) Brick trowel (Thapi):- Brick trowel is usually about 18 cm long with a steel blade and wooden handle. Brick trowels are used to pick up mortar and spread it in the level for the next course of brick. It is traditional tool which has developed into many various shapes and sizes. The blade being flat on one side for lifting the mortar from the pan. The curved edge is hardened for cutting bricks. The handle is set at an angle to balance the tool while keeping the mason’s hand clear of the mortar.

b) Nyla (Small size brick trowel) :-It is also a trowel but smaller size having length about 12.5cm and used to mainly fill the joints between the bricks.

c) Margin trowel: The margin trowel is like a pointing trowel but has a flat rectangular blade. It is used by plasterers to apply and smooth material in areas where a larger trowel would be inconvenient.

d) Gauging trowel: – The gauging trowel having blade length 15cm to 20cm is used by plasterers in the same way as a margin trowel. It is preferred by some masons for general application, such as mixing small quantities of quick setting plaster

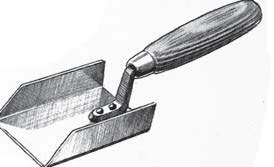

e) Angle trowel: – The angle trowel has a flat blade with the edges turned up at right angles of size length 100mm x 62mm wide and 25mm height. It is used by plasterers to smooth the surface of the material when working in to a corner.

2.2 Floats

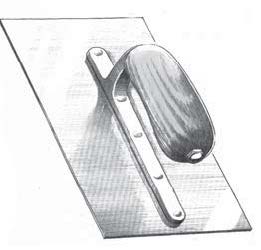

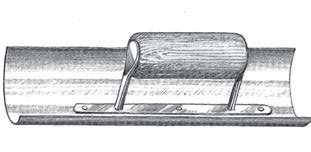

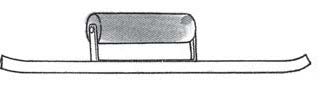

a) Wooden float (Randha):- Wooden strip of 50 cm length and 10 cm width with handle used for laying mortar in line on brick work, some times at the time of plaster also. It is also available in smaller sizes such as 25cm x 10 cm.The main purpose of using floats is to fill voids, level ridges and smooth the surfaces in the preparation of troweling.

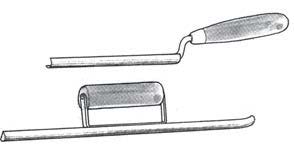

b) Metal float: The metal float is a flat rectangular sheet of steel normally 25cm x 10cm with a handle fitted centrally down the back face. Its general purpose is for both applying and finishing the material, applying sanla or neat cement finish to plaster.

c) Plumb Bob (Olamba): Plumb bob is a basic tool for mason to construct any masonry work in vertical plane. It is available in normally mild steel with coating having weight about 30-40 gms.The plumb bob is pointed weight attached to a length of line which is contained in the bob itself and fastened in a slot in the cap

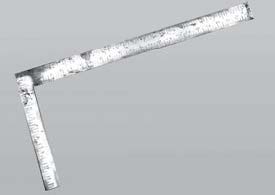

d) Mason’s square(Gunnya): This is used to set out a right angled corner. It is M.S. square having 30cm x 60cm long arms with inch or Cms marking. It is used for laying corner of bricks in rectangle also measurement of width of wall.

e) Line dori: This also required by any mason as a basic tool for doing the work in line. Normally a jute dori of 3mm dia. with wax coating is used. Nowadays nylon line dori are quite in use it may be of 1mm to 2mm dia.

f) Screed boardl Aluminium Hallow box section: Screed board is used for leveling the surface at the time of plastering and flooring work. It may of wooden batten of size 50mm x 65mm of length 1.2m to 1.5m. A aluminium hallow box section of size 65mm x 30mm and 1.5m length is also used. This can be named as straight edge.

g) Measuring Tape:- A steel tape having marking in Metres and foot and subdivided in Cms and inches is normally used by mason for measuring the length and width of masonry. It is available in 2m, 3m, 5m, 15m and 30m in length.

3.0 Mortar Making tools:

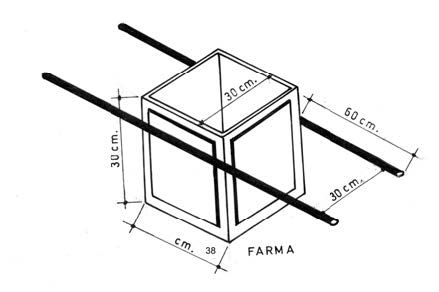

a) Pharma: It may be wooden or steel box of measurement 30cm x30cmx 30cm having volume equal to volume of one bag of cement. While dumping raw material for mortar (say 1:4), for one bag of cement 4 pharma sand will be mixed.

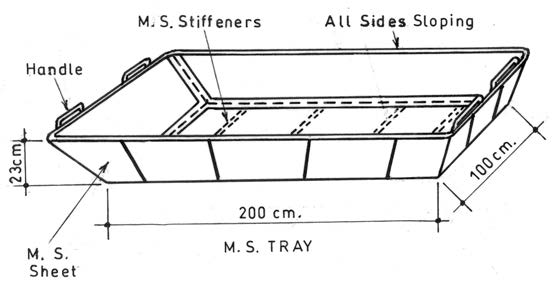

b) Mixing Tray: For mixing mortar the tray made up of mild steel is used generally. It is 2.0m in length and 1.0 m wide with handles as shown.

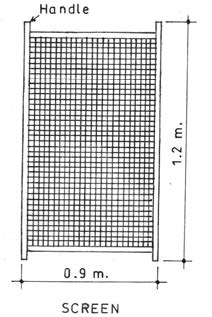

c) Sand screen: Generally a wire mesh of overall size 0.9m x 1.2m fixed on wooden frame or angle frame used as screen for sand. The screen is made up of 0.6mm dia.wires and 10 x10 wires per inch square for masonry work.

For plastering work a screen having 0.3mm dia of wire with 24 x24 wires per inch square.

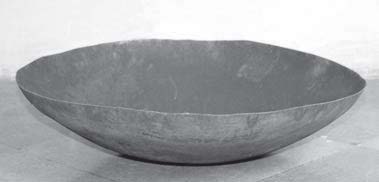

d) Pan (Ghamela) : For transportation of mortar a iron pan of 40cm dia is used. It can be used for proportiong the mix also. If there is 1:4 mortar mix then 1 pan of cement can be mixed with 4 pans of sand

e) Spade (Phawra): It is most common tool for mixing the mortar and for filling the pans.

f) Bucket: Generally an iron bucket of up to 10 lit. capacity is used for mixing the water in the mortar.

g) Drum: A 200 lit capacity M.S. drum is used to store the water. Now-a-days PVC containers are also available.

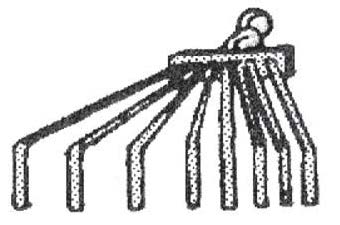

h) Panja: A group of 8 to 10 wires of 6mm M.S bars of length 500mm and these wires are bent at 90 degree at edges (as shown in fig.) is very useful tool for spreading the concrete in particular area with required thickness.

4.0 Leveling Tools

a) Spirit level: This is the most important tool with help of which level between any two surfaces can be judged by movement of bubble. Normally this instrument is used for tiling work for checking level of tiles.

It is normally 30 cm long. The important part of any level is the vial. This is curved or barreled glass or plastic tube containing a clear liquid which may be alcohol, oil or chloroform. There is a bubble of air in liquid which floats to the highest point of the curve, where two lines are marked on the vial. When the level is “true” the bubble will come to rest between the two marked lines.

b) Level Tube: A thin 6mm dia PVC transparent tube of about 8-10m. in length and is used to check the levels when filled with water. Basic principle is that water will occupy same level, is used for making the work in level.

5.0 Finishing Tools

a) Sponge: A square of sponge of size 12.5 cm x 10 cm is used to finish plaster surfaces as sand faced plaster. By applying two to three rounds of this sponge fine texture of sand will appear on surface.

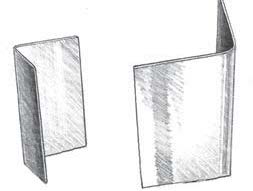

b) M.S. Corners: Small pieces of MS sheet of about 12.5 cm in length and used for perfectly finishing of corners of wall and edges of door and window plaster.

c) Cove Corner: The cove corner is like a metal float, but the rectangular blade is bent in to a curve across its width. It is used to smooth the internal curve of the decorative plaster moldings sometimes found between ceilings and walls.

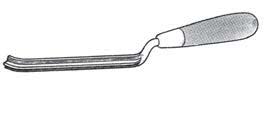

d) JointerlSlicker:- It is having a blade length of 12.5 to 30cm with hard wood handle and used to finish the mortar joints between bricks. The mortar joints between bricks must be formed in order to make them weatherproof and to improve the appearance of the brick work.

e) Convexlconcave Jointers: It is also a blade length 12.5cm to 30cm. This is used for finishing the joint in concave joint.

f) Vee-Jointer: It is also a blade length 12.5cm to 30cm and looks like concave jointer but has a deep, sharply angled blade for finishing V shaped joints.

g) Grapevine Jointer: Same as per convex jointer but having shape as in drawing having central rib for a decorative flat joint with a deeply impressed shadow line in the centre.

h) Brushes: At least two types of brushes 25mm wide and 75mm wide brush should be with mason for cleaning the surfaces and finishing work.

6.0 Cutting Tools

a) Chisel and Hammer: Various types of chisel and hammer are available in market but mason should have at least two types of hammers which weigh 1 pound and 4 pounds for dismantling work and chisels of size 10cm for small work and 20 cm for major work of dismantling.

b) Taccha: It is just like a hammer but having both ends pointed edges and used for hacking the concrete surfaces of beams and columns or slabs before plastering, for better bonding. Some taccha have one point as pointed sharp for deep hacking.

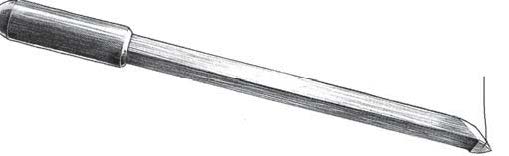

c) Tile cutter: The simplest tile cutter is a square sectioned steel shaft of 20cm length with a pointed tungsten carbide tip. It is used to score a line on the glazed surface of a ceramic tile prior to snapping it off.

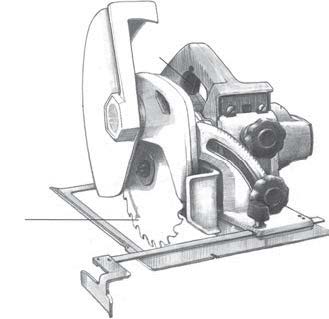

d) Portable Circular saw: The portable circular saw is an invaluable power tool. It is primarily a woodworking tool, but with special tile cutting blades it can be used to cut the ceramic as well as other types of tiles.

CONTENTS

Chapter 1 Mason’s Tools

1.0 Various tools

2.0 Common tools

3.0 Mortar Making tools

4.0 Levelling tools

5.0 Finishing tools. 6.0 Cutting tools

Chapter 2 Materials

1.0 Cement Fine aggregate (Sand)

2.0 Stone aggregate Bricks

3.0 Steel Reinforcemet Bars

4.0 Concrete blocks

5.0 Floor and wall tiles

6.0 Interlocked paver blocks

Chapter 3 Excavation of Foundation

Lineout of buildings

Soils of foundations

Field indentification of soils

Suitability of soil for foundation Bearing capacity of soil

Method of excavation

Guidelines of foundation work

Chapter 4 Brick /Stone Masonry

General Mortar

Bonds in Brick mason…

Strengthening the building to make them fit for Seismic Resistance

UCR masonry work

Chapter 5 Plastering Work and Pointing Work

1.0 General

2.0 Thickness of plaster

3.0 Types of plasters

4.0 Proportions to be used

5.0 Preparation of external plaster Intemal plastering

6.0 Precautionary measures to avoid cracks in plaste

7.0 Pointing work

Chapter 6 Flooring and Tiling

1.0 Introduction

2.0 IPS flooring

3.0 Brick flooring

4.0 Tiles and stone flooring

5.0 Interlocking paver blocks

6.0 Guidelines for flooring for different types of works

Chapter 7 Cement Concrete

1.0 Introduction

2.0 Raw material used in PCC and RCC

3.0 Properties of Wet concrete

4.0 Mixing of concrete 5.0 Ready mixed concrete

5.0 Placing of concrete

6.0 Water proofing for water closet where sink is provided

7.0 Water proofing of bathrooms

8.0 Junction of roof with parapet walls

9.0 Expansion joint

10.0 Outlets for rain water pipes

11.0 Water proofing of chajjas

Chapter 8 Staircase, Lintels and Chajjas

1.0 Staircase

2.0 Lintels and Chajjas

3.0 Sunbrakers

New Zealand Concrete Masonry Manual

New Zealand Concrete Masonry Manual